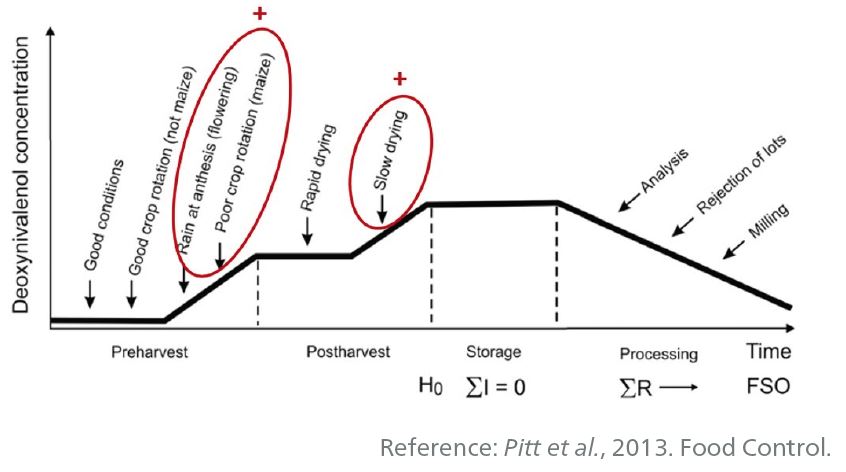

Mycotoxins are known to present a dynamic risk to feed quality

The challenge initially starts in the field with Fusarium toxins such as the trichothecenes, zearalenone and fumonisin, or the Aspergillus species like aflatoxin. However, even if the feedstuff is not directly contaminated at the time of harvesting, the quality of harvested grains and forages can deteriorate significantly during storage. If the right conditions for mycotoxin proliferation are met over the months of storage, the feed that the animals eventually consume may pose just as much of a problem.

This post-harvest mycotoxin risk can come from the exacerbation of mycotoxins that were already present pre-harvest, or the development of Penicilium toxins, such as ochratoxin and citrinin, which more commonly develop during the storage of ingredients and feedstuffs. There are several key management practices that producers can use to limit the potential risk of fungal growth and mycotoxin contamination in stored grains and forages, helping to reduce the threat to animal productivity and farm profitability.

Management of grain during storage

Moisture, incorrect grain temperatures or insect damage can all provide the necessary conditions for fungi to thrive during grain storage. To help avoid these issues:

For short-term storage, dry grain to less than 16% moisture content as soon as possible after harvest. For longer-term storage (6-12 months), grain should be dried to less than 14% moisture

- Avoid moisture build-up and maintain sufficient aeration in grain stores and silos (regular maintenance of aeration systems is important to sustaining optimum performance)

- Regularly monitor grain temperatures and humidity

- Maintain effective insect control

- Inspect stores and silos for leaks or build-up of moisture

- Thoroughly clean and inspect stores and silos between different batches of grains and feedstuffs

- Where practical, ingredients should be used in a ‘first in, first out’ manner

- Application of a mould inhibitor, such as MOLD-ZAP® can help to reduce fungal growth

- Establish a detailed monitoring program with a clear set of standard operating procedures (SOPs)

Management of forage during storage

As mould requires oxygen to grow, attaining and maintaining an anaerobic environment is key to reducing growth and subsequent mycotoxin risk. This can be achieved by:

- Ideally, ensiling all forages at between 32-36% dry matter (DM)

- Sealing the clamp thoroughly and regularly monitoring to ensure an anaerobic environment is maintained throughout storage

- Using a sharp feed-out tool to remove forage from the clamp Moving across the feed face as quickly as possible (ideally, five days maximum)

- Preparing the total mixed ration (TMR) using forage freshly removed from the clamp and feeding immediately

- Removing uneaten feed daily, prior to placing fresh feed in front of the livestock

- Ensuring all mixing and feed areas are kept clean and free of mouldy feed residues

Testing for mycotoxins

As part of an effective mycotoxin control plan, regular testing can play a crucial role in measuring how the risk of mycotoxins is evolving during the storage period. Rapid testing tools like Alltech® RAPIREAD™ provide a quick and inexpensive way to carry out mycotoxin testing on-farm or in the feed mill. Using this in combination with Alltech 37+® mycotoxin analysis will ensure that the most effective decisions can be made regarding the adjustment of management practices or the potential need for a mycotoxin adsorbent to reduce the threat to animal productivity.

Proper sampling is crucial to delivering accurate mycotoxin testing. Alltech has prepared a comprehensive guide to assist producers in ensuring the most representative ingredient and finished feed samples are sent for testing. Visit knowmycotoxins.com to find out more.

Mycotoxin binders

As productivity in modern animal production increases, so do the challenges and risks that can affect herd health and performance. Many moulds and mycotoxins are undetectable by a visual assessment alone.

It is important to safeguard your animals and include Mycosorb A+ a proven broad spectrum mycotoxin binder, which tackles mycotoxin challenges as a whole, rather than dealing with individual mycotoxins.

Please contact your Alltech Lienert sales representative or nutritionist to discuss grain quality, testing for moulds and specific information on tackling mycotoxins in your feed. Call 1800 649 231.